Production Process

EDO-SASHIMONO is made by hand, and a craftsman has the responsibility for all the making process until completion.

Dry Drying-out naturally for more than 6 months

Sashimono is made from mulberry, cedar, Japanese zelkova, tamo, or amur cork. Wooden materials need to dry for at least 6 months to 20 years long naturally.

Measurement & Cutting Measurement and mark on board, then cutting

Plane off To make a wood smoother and flatter.

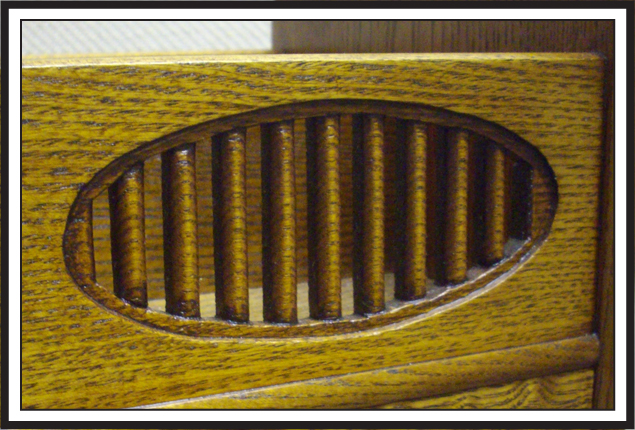

Kumite, Koana, Hozo Work Making of each product

Building Put together all the parts with glue and wooden pegs.

Finishing Plane off the surface

Polish Polish the products with equisetum, althea, and sandpaper.

Lacquering Repeating the process of coating and wiping for more than 10 times

until the wood gets shiny.

Hukiurushi Variety of lacquering method: Roiro-nuri, Nuri-tate, Mehajiki-nuri etc

Lacquering chamfer, gold or silver lacquering, mother-of-pearl work, sculpture etc

Attachment of Metal parts Attach a hinge and handle